Choosing the Right Infill Percentage for your 3D Print

Share

When it comes to 3D printing, one of the critical factors influencing the strength, weight, and material usage of your printed object is the infill percentage. Understanding and selecting the appropriate infill percentage for your specific use case can significantly impact the performance and quality of your final print.

What is Infill?

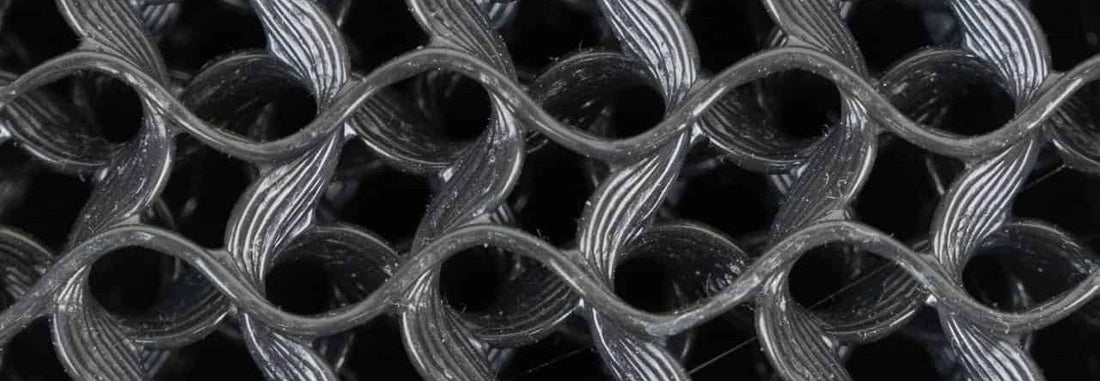

Infill refers to the internal structure of a 3D printed object. Unlike the solid outer walls, the infill is the internal lattice-like structure that supports the object, providing stability and strength. The infill percentage determines how dense this internal structure is, ranging from 0% (completely hollow) to 100% (completely solid).

Commonly used gyroid type infill

The Effect of Infill on a Print

Strength and Durability:

- Higher Infill Percentages: Increase the strength and durability of the print. A higher infill means more material is used inside the object, which can support more weight and withstand more stress.

-

Lower Infill Percentages: Result in a lighter but less strong print. These are suitable for objects that don’t need to bear much load or stress.

Weight:

- Higher Infill Percentages: Lead to heavier prints. This can be desirable for parts that need stability and weight, like bases or structural components.

- Lower Infill Percentages: Create lighter prints, useful for parts that need to be moved or carried frequently.

Material Usage:

- Higher Infill Percentages: Consume more filament, increasing the cost of the print.

- Lower Infill Percentages: Save material, making the print more cost-effective.

Print Time:

- Higher Infill Percentages: Increase print time due to the additional material and complexity of the internal structure.

- Lower Infill Percentages: Decrease print time, allowing for faster production.

Low, medium and high grid infill percentages

Recommended Infill Percentages for Different Use Cases

-

Prototypes and Models:

- 10-20% Infill: Ideal for visual prototypes and models that don’t require much strength. This keeps the prints light and saves material and time.

-

Functional Parts:

- 25-50% Infill: Suitable for functional parts that need to withstand moderate stress and wear. This range provides a good balance between strength and material usage.

-

Structural Components:

- 50-100% Infill: Best for parts that need to bear significant load or stress, such as mechanical components, tools, or parts under constant use. This ensures maximum strength and durability.

-

Decorative Items:

- 0-15% Infill: Perfect for decorative items like figurines or ornaments that don’t need to be strong. This saves material and keeps the prints lightweight.

-

Medical and Safety Equipment:

- 60-100% Infill: For items that must meet high safety standards or endure harsh conditions, a high infill percentage is essential to ensure reliability and robustness.

Range of different infill percentages.

Conclusion

Choosing the right infill percentage is crucial for optimizing your 3D prints for their intended use. By understanding how infill affects the strength, weight, material usage, and print time, you can make informed decisions to achieve the best possible results. Whether you’re printing a lightweight prototype or a durable functional part, selecting the appropriate infill percentage will ensure your prints meet your needs effectively.

At Aussie Print Labs, we offer expert advice and high-quality 3D printing services to help you achieve your goals. Contact us today to discuss your next project and discover how we can bring your ideas to life with precision and efficiency!